Tag: Crafts person

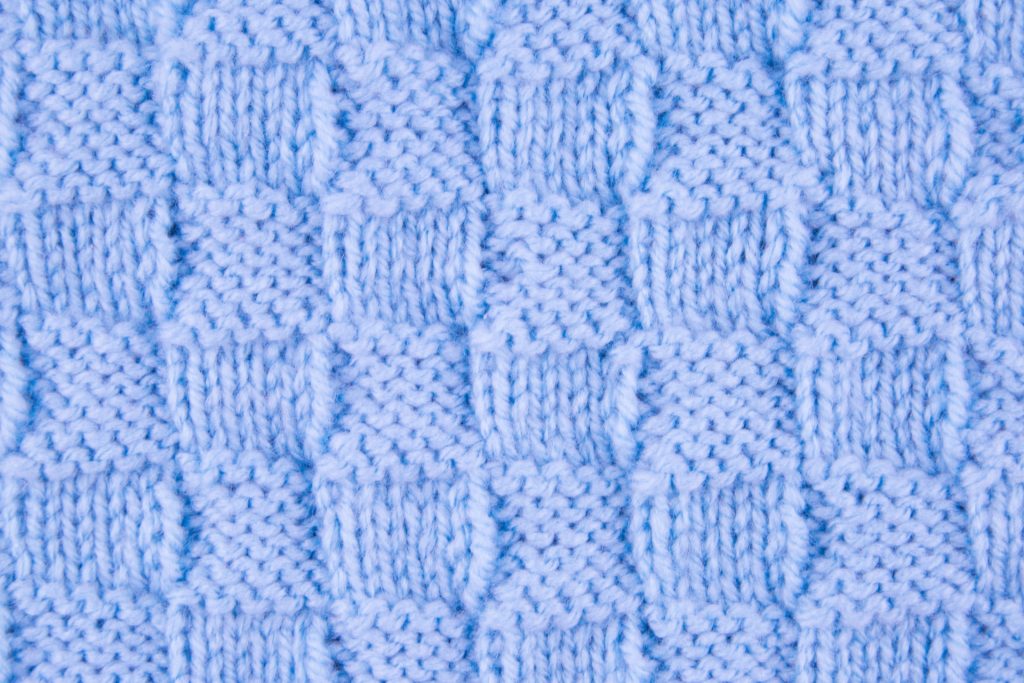

How to Knit in Jersey

How to Knit in Jersey Contents – Knitting in purl jersey – Knitting in purl stitch – Adding selvage stitches in stockinette…

How to Use a Router

How to Use a Router Contents – Focus on safety rules – Step 1: Start the router – Step 2: Rip and steer a router…

3 DIY Tips for Making a Natural Shower Gel

3 DIY Tips for Making a Natural Shower Gel Contents – Step 1: Make an invigorating shower gel – Step 2: Make a…

5 Steps to Driving a Nail Like a Pro

5 Steps to Driving a Nail Like a Pro Summary – Step 1: Adopt the correct postures – Step 2: Case 1: Hold the large…